Injection Molding

Red Star uses the latest technology to lower costs while ensuring customer satisfaction.

Red Star can place its team against any of our competitors and feel confident that our experience with the intangibles associated with insert molding over the last 25+ years far outweighs the team they bring to the table to solve your insert molding needs.

Over-Molded Products

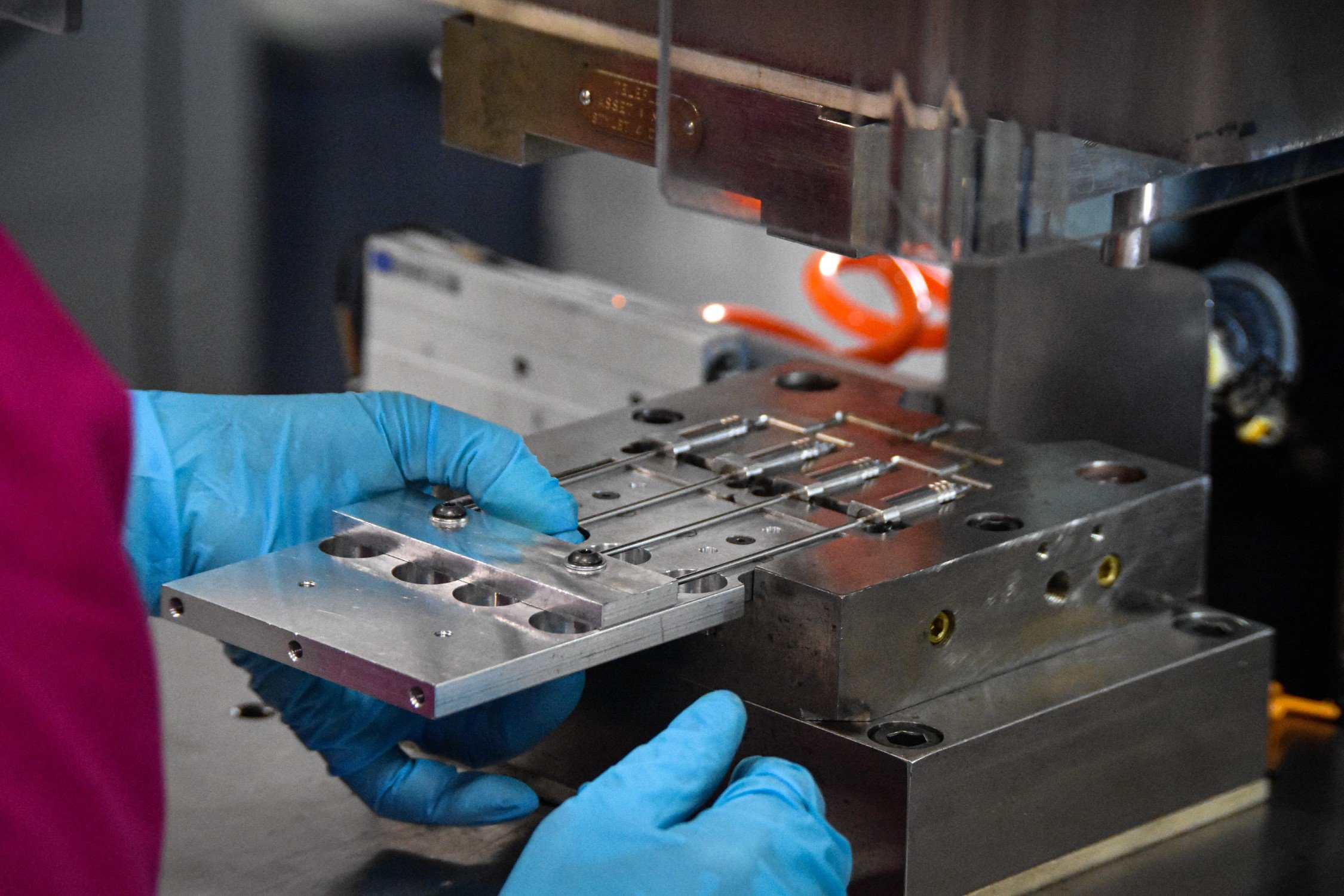

Using Metal and Polymer Inserts for Biospy and Orthopedic Instruments

Multiple Cavity Molding

Increasing production efficiency is our specialty.

MOlded Handles

Handles to fit any tool and use. Handles can be molded as single or multi-material.

Mold Design & Build

Prototyping

Assembly

Multiple Cavity Molding

Horizonal & Vertical Presses

Smooth & Textured Surfaces

Materials

PEEK – POLYETHER ETHER KETONE

RADEL – POLYPHENYLSULFONE (PPSSU)

ULEM – POLETHEREIMIDE (PEI)

LEXAN - POLYCARBONATE

CYCOLAC - ABS

CELCON - ACETAL

DESMOPAN - POLYURETHANE

POLYPROPOLENE - PP

NYLON

SANTOPPRENE - TPE

IXEF

Over Molding

Plastic Components

Retention Hubs

Cannula

Biopsy Needles

Catheter Products

Single-Use Instruments

Drivers

Drills

With the use of our specialty machines, scientific molding practices, and state-of-the-art equipment we can manufacture lower-cost medical/biotech products in our ISO Class 8 cleanroom. We have molding machines ranging from 10 tons to 110 tons with variable shot sizes to make any project possible.

-

Using Metal and Polymer Inserts for Biospy and Orthopedic Instruments

-

-

Radel, Ryton, Glass Filled Nylon, Polycarbonate, Urethane, Polypropylene, ABS, Ultem, PEEK, and Santoprene.

-

Biopsy Needles, Catheter Products, Single Use Instruments, Overmolded Orthopaedic Instruments, Specialty Cannulas and more

-

Designed for assembly and packaging

Red Star specializes in overmolding for Orthopaedic instruments

Overmolding is a process wherein plastic resin is molded around a part made of another resin without removing the part from the molding press. This may be accomplished either by use of a robot, or a rotary platen within the molding press.

Typically, 2 different resins with different physical or chemical properties are used to create an assembly complete from the molding press in a single process.

Some common examples are:

Finished plastic parts with multiple colors

Instrument handles or controls with a soft-grip surface molded over a rigid base

Mechatronic assemblies using resins with different shrink rates to create movable multi-part assemblies

Valves and seals requiring a low durometer sealing surface on a rigid structural base

Get Help with

Your Next Project

Red Star is an ISO 13485 Certified, FDA Registered, Certified Full-Service Contract Manufacturer.

Tell us what help you need with your next molding, assembly, and packaging project.